Jiko

Automated Pre-Roll Infusion Robot

Flawless Pre-Rolls, Enhanced Quality, Better Returns.

How Jiko transforms your production:

Infuse Live Rosin & Melt-able Concentrates

Perfect for infusing a wide range of high-quality concentrates. create a solid core of concentrate down the center of your preroll.

Customized Fit for All Pre-Roll Sizes

Works seamlessly with pre-rolls, blunts, cones, and straight tubes of any size.

Single-Person Operation

Infuse up to 1,000 pre-rolls per hour with ease, all by one operator.

Create & Save Custom Infusion Profiles

Tailor your infusion process to specific product needs and save for future use.

Product Overview

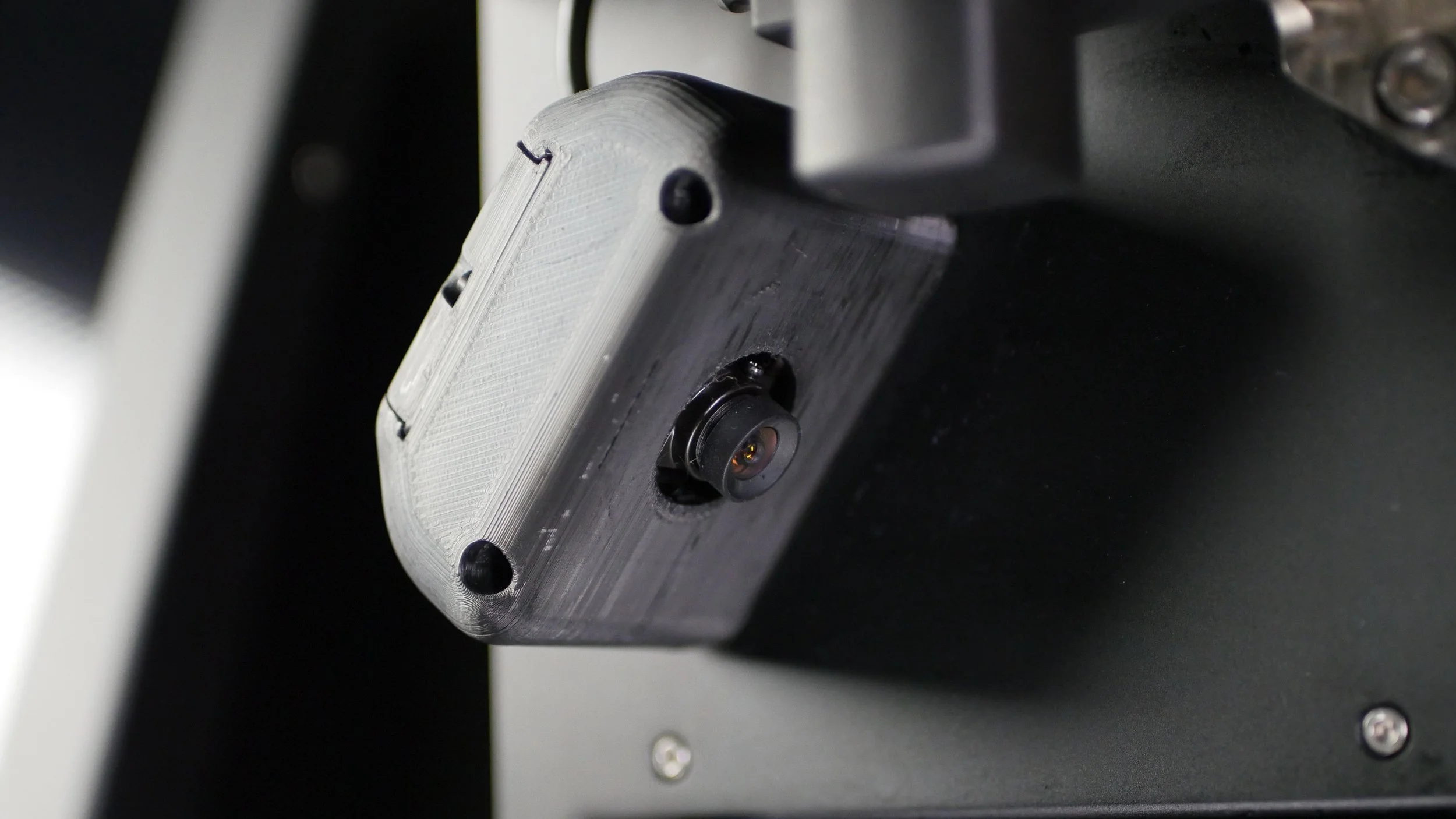

Jiko is designed to infuse various sized pre-rolls. The system utilizes both pressure and temperature to control the infusion process. Moreover, a sophisticated touchscreen interface allows the user to adjust settings to accommodate the type of concentrate being infused.

U.S. Patent 11,800,890 / U.S. Patent 11,903,409 / Canadian Patent 3,110,385

-

An automated preroll infusion machine that injects a core of concentrate into any sized pre-roll or blunt.

-

In stock and ready to ship. Schedule a demo to get yours!

-

Reduce labor costs, minimize spillage, and create premium infused prerolls that sell at higher margins. See a return on your Jiko investment in one year.

-

Light daily cleaning with scheduled maintenance.

-

Each machine gets a dedicated slack channel for support and service inquiries.

-

Jiko can infuse 1,000 pre-rolls per hour

-

Any type of meltable concentrates: Decarbed Rosin, Decarbed Live Resin, Distillate, HTE, Sauce, CBD, D8, HHC.

-

Pre-roll wheels can be interchanged to accommodate any size joint or blunt.

For Product Specifications, Size and Dimensions and Product Requirements:

What do customers say about Sorting Robotics?

See our improved pre-roll quality for Blenz Cannabis.

GoodTimes New York highlights how Sorting Robotics allows for customization in their products.

See the results for yourself.

Jiko is just the start.

See what else we automate.

Jiko+

Go beyond the basics with Jiko+: automation that adapts to your growing business needs.

LAKA Production Data

Native Production Analytics software and Real Time Monitoring - included on all Sorting Robotics solutions.

Stardust

With Stardust, infuse, coat, and create premium products faster and more consistently.