Flower to Distillate Yield

Distillates are one of the most popular ways of enjoying the potential benefits of cannabis. In the realm of cannabis extraction, achieving an optimal flower to distillate yield is an essential aspect to comprehend for producers and consumers.

This is because the final distillate obtained by a given flower material is a crucial metric influencing product quality and economic viability. In essence, the yield ratio is a pivotal metric that shapes the dynamic of production efficiency.

Let’s dive into the definition and explore its significance in this post!

Source: shutterstock.com / Photo Contributor: Mathias Alvez

Understanding Flower to Distillate Yield

The term ‘yield’ refers to the quantity of valuable compounds, such as cannabinoids and terpenes, obtained from the raw flower material during extraction. For cannabis producers, having a profound understanding of the flower distillate yield is essential.

This is because it directly impacts production costs and profitability. A high yield indicates an efficient production process, translating to more product per unit of starting material. On the other hand, low yield may prompt producers to revisit and refine their extraction methodologies.

Conversely, you may also benefit from this knowledge and a high-yield scenario. The yield can signify the potency and the value of the cannabis product of their choice. A good understanding of this metric helps you make more informed choices about the potency and the quality of the products you purchase.

How yield is measured and calculated?

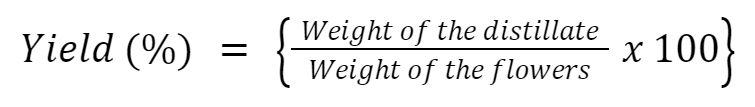

Measuring and calculating the yield involves accessing the concentration of desired components in the final distillate in relation to the initial flower material. It is typically expressed as a percentage and indicates the extraction efficiency.

So, how much distillate per pound of trim? Flower to distillate is a critical metric in cannabis processing that represents the efficiency of extracting essential oils from the flowers. It is generally calculated as the ratio of the weight of the distillate to the weight of the flowers used in the extraction process.

The metric can vary based on several factors, including the quality of the starting material, extraction methods, and equipment efficiency. The formula for trim-to-distillate yield is the following:

Factors Influencing Yield

Now that you are familiar with the significance of yield in cannabis extraction, let’s get into the factors that influence the flower to distillate yield.

Quality of the starting cannabis flower

The foundational factor influencing the flower to distillate yield is the quality of the starting cannabis flower. High-quality cannabis flowers cultivated with care and attention commonly have a richer cannabinoid and terpene profile.

The plant's overall health and maturity also significantly impact the final yield. A robust and quality starting material sets the stage for making potent and valuable cannabis distillate. Hence, if you are aiming for an elevated yield, you must prioritize the cultivation of top-grade cannabis plants.

Influence of cannabinoid and terpene content

The cannabinoid and terpene content in the cannabis flower has a crucial role in yield. Given that different strains exhibit varying concentrations of these compounds, they affect the overall potency and flavor of the distillate.

That is, varieties with higher concentrations of cannabinoids and a diverse terpene profile often boast superior quality. So, cannabis producers must carefully select strains that align with their desired product for a successful outcome.

Impact of flower freshness and storage conditions

The state of the cannabis at the time of extraction is crucial for yield. Dry flowers may yield less desirable compounds. The same applies to flowers that have undergone degradation due to poor storage conditions. In contrast, properly preserved and well-hydrated flowers often contribute to a more efficient extraction process.

Extraction methodology

The choice of extraction methodology also profoundly impacts flower to distillate yield. This is because each method brings nuances to the yield equation. As a result, you must carefully select the method, considering factors such as efficiency, selectivity, and safety.

Many cannabis producers opt for solvent-based methods as they excel in yielding high percentages. Yet, some may prefer supercritical CO2 extraction due to its precision and enhanced purity. Given its versatility, ethanol extraction presents a viable option for achieving the desired yield.

The efficiency of the extraction process and equipment used

The efficiency of the extraction process significantly relies on the equipment you use. State-of-the-art extraction equipment is crucial for maximizing yield. It is designed to optimize the separation of cannabinoids and terpenes from plant material.

Source: shutterstock.com / Photo Contributor: pancakenap420

Processing parameters

Fine-tuning processing parameters add a layer of control to the extraction process. That said, precise control over processing parameters is essential for achieving a high yield level. What we mean by this is that variables such as temperature, pressure, and time directly influence its efficiency.

Optimal conditions ensure a thorough extraction of cannabinoids and terpenes while minimizing the degradation of sensitive compounds. Therefore, you must tailor extraction conditions to the specific characteristics of the cannabis strain to preserve the quality of the final distillate and achieve a desirable yield.

Yield Ratios and Expectations

While yield ratios vary, the common benchmark is a 10-20% yield of cannabinoids and terpenes from the starting cannabis flower. This is the baseline for achieving efficiency throughout the extraction process.

An important thing to mention is that these figures serve as broad averages. The outcomes may vary based on numerous factors and specific circumstances.

Variability in yield ratios based on extraction method and expertise

As we previously mentioned, the choice of extraction method can profoundly impact the yield ratios. Hence, an equally significant defining factor is expertise. An experienced extraction team can optimize yield regardless of the chosen method.

Realistic ranges and benchmarks for yield expectations

Realistic yield expectations depend on various factors. These include strain selection, cultivation practices, and extraction methodologies. Using top-grade cannabis flowers and cutting-edge extraction, yields above 20% are achievable.

However, you also need to consider factors such as the complexity of the extraction method, the desired purity, and the overall efficiency of the process. Benchmarking against industry standards and similar operations can provide valuable insights. For example, comparing yields with facilities using similar methods and equipment can help you gauge the processes' competitiveness and identify improvement areas.

Maximizing Yield: Best Practices

The role of using advanced equipment in maximizing yield cannot be overstated. In cannabis production, achieving optimal flower to distillate yield is paramount.

We provide cutting-edge automated cannabis production machines that enhance efficiency and maximize yields. Our innovative technology aims to usher in a new era of precision and productivity in the cannabis extraction landscape.

Importance of selecting high-quality starting material

The foundation of a high yield ratio begins with a selection of premium starting materials like the cannabis flower. With this in mind, opting for a strain with robust cannabinoid and terpene profiles is crucial for enhancing overall extract quality.

Moreover, quality cultivation practices, such as precise nutrient management and ideal harvesting conditions, contribute significantly to the potency of the starting material.

Optimization of extraction parameters for maximum yield

Adjusting the extraction parameters is an art you must master to unlock the yield’s full potential. This includes fine-tuning variables such as temperature, pressure, and extraction time.

Striking a balance between efficiency and selectivity ensures that the extraction process maximizes the yield of desirable cannabinoids and terpenes. At the same time, it minimizes undesirable byproducts.

Ensuring proper equipment maintenance and process control

Regular maintenance checks and adherence to strict process control protocols are indispensable for yield.

In addition, properly calibrated and functioning equipment contributes to the consistency and reliability of the extraction process. Routine inspections, cleaning, and calibration routines safeguard against inefficiencies that could compromise yield.

Aside from equipment, meticulous process control is equally critical. Operators must monitor and adjust parameters in real time and promptly respond to variations that might impact yield.

Source: shutterstock.com / Photo Contributor: MR.Yanukit

Conclusion

The flower to distillate yield ratio is a pivotal indicator in the extraction landscape, shaping the dynamics of production efficiency and consumer choices. The journey toward maximizing yield is a multifaceted endeavor requiring a holistic approach. This includes selecting a top-grade starting material, using proper equipment, optimizing the extraction parameters, and maintaining the equipment properly.