RocketBox 2.0 Review

Is your company looking for high-volume production and efficiency? This is your sign to invest in a rolling machine. To help you choose the best one on the market, keep reading through this RocketBox 2.0 review.

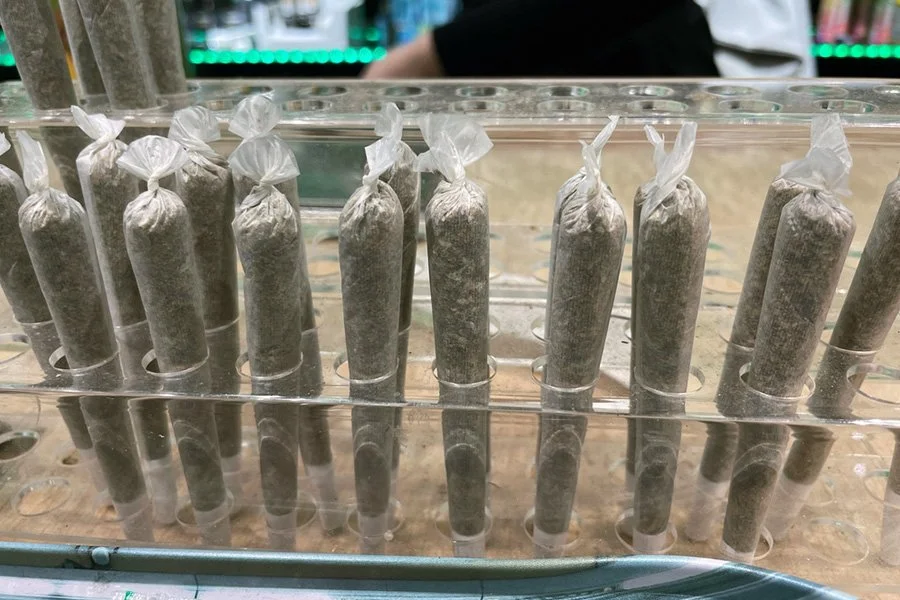

This industrial pre-roll device offers state-of-the-art technology and produces 453 rolls per cycle. Thus, it’s one of the fastest and most reliable rolling machines your company can benefit from.

Whether you are just starting to take an interest in the cannabis industry or you already have a well-established facility, RocketBox 2.0 can change your production game. Also, this modern device is easy to use and has adjustable settings.

Source: stmcanna.com

Background and Significance

Hand-rolling joints are a thing of the past. Machines have made it easier for companies and their employees to produce precise and consistent rolls in a matter of a few minutes. Smokers nowadays prefer purchasing pre-rolls rather than wasting time on making their own.

Cannabis companies can fill and pack dozens of pre-rolls quickly with pre-roll machines similar to RocketBox 2.0. This way, they maximize capacity and cut down labor costs in some American states and Canada, where marijuana is legal.

Technical Features and Functionality

The STM Canna RocketBox 2.0 pre-roll machine is engineered with industrial-grade components, making it extremely durable and fast. This commercial roller has the ability to withstand the pressure of high-volume production.

The sturdy construction of this rolling machine comes from its stainless steel frame. The high-quality materials make this device resistant to corrosion. All of the parts and components included in this joint roller are highly functional regardless of how often it’s used during roll production.

The technical features of this machine are impressive enough. But companies also appreciate the fact that RocketBox 2.0 comes with certain additions that make production easier, more professional, and highly efficient.

If you decide to purchase this rolling machine for your company, you will get a 453-joint bottom tray, a 453 top tray, a loading box, a finishing base, and a density testing beaker.

Quality and Consistency

The RocketBox 2.0 rolling machine has user-friendly features and design. Thus, it can easily and efficiently fill and pack up to 25,000 consistent pre-rolls daily. Its functionality comes from its high-quality characteristics and durability.

Every unit of this rolling machine is constructed using stainless steel. This material is easy to maintain due to its sturdiness and quality. Its design is compact and perfect for facilities that don’t offer too much free space.

This industrial/commercial rolling machine is compatible with different cone sizes, including 84 millimeters, 98 millimeters, and 109 millimeters, to offer ultimate consistency.

Pros & Cons

| Pros | Cons |

|---|---|

| Durable | The machine’s slots are too big for cigarette-rolling paper |

| Consistent rolls | |

| Various cone sizes | |

| 25,000 pre-rolls per day | |

| Fast production | |

| Low maintenance |

Specs

| Brand | STM Canna |

| Weight | Around 300 pounds |

| Warranty | 12 months |

| Dimensions | 24″ L x 37″ H x 27″ W |

| Voltage | 110 volts |

| Material | 304 stainless steel |

| Software | USB port for programming |

| Touch Screen | HD 7″ touch screen panel |

| Cord Length | 5-1/2′ cord |

| Longevity | 10 years |

Maintenance and Upkeep

To preserve the quality of your pre-roll machine, you must offer regular upkeep and maintenance. This practice can make the RocketBox 2.0 rolling machine last longer. It can also prevent troubleshooting issues and any possible damage to the pre-rolls.

To keep your joint roller clean, you must use non-corrosive products. This is to avoid damage to the stainless steel material. Although there are many solvents you can purchase, simple solutions like warm water and mild soap also work wonders.

Use a gentle, small brush to clean the inside of the machine and get rid of any dust or debris that might be built up. But remember that every rolling machine also comes with maintenance instructions recommending which cleaning products work best.

Source: stmcanna.com

Economic Considerations

The use of RocketBox 2.0 may help companies reduce labor costs. Due to its efficiency and fast production, businesses can cut down on the number of employees needed during the equipment operation.

A single employee can control this rolling machine, and it includes training manuals that make it easier to operate. This way, your business will meet the necessary demands and increase ROI fast.

The machine also comes with a one-year warranty on the parts and labor. But the warranty can be extended if the company demonstrates double production.

Regulatory Compliance

The company STM Canna is clearly aware of the importance of regulatory compliance and state rules. They are OSHA compliant, meaning their practices are aligned with the protective methods used in the facility to shield employers from possible danger and health risks.

The RocketBox 2.0 pre-roll machine has food-grade materials. This is to ensure that the produced pre-rolls can be safely consumed. Thus, this machine is designed using materials that meet food safety standards to prevent contamination and prioritize customer safety.

The production and packaging process of marijuana products requires businesses to follow strict state rules. Regulatory compliance keeps them operating legally. Following the rules and regulations of the industry also protects the company’s reputation.

This industry also requires regular maintenance of the equipment and demonstrated quality control. Pre-roll machines must meet the industry’s established standards, including weight, size, and packaging parameters.

Irregular cleaning and sporadic maintenance of the rolling machines businesses use during production may lead to product contamination. In such cases, the companies are seen as not compliant with industry standards and risk the potential of creating health hazards.

Challenges and Future Directions

Pre-rolls are very popular among smokers. Cannabis companies also love making them through pre-roll machines, thus increasing their revenue easily. By using these machines, customers avoid hand-rolling, and businesses focus on packaging and proper measurements.

But just like any other process, the production process of joints may come across some challenges, even if done with modern devices. Some companies use improper pre-roll packaging, resulting in an inconsistent burn and product quality damage.

The biggest mistake businesses can make is storing their cannabis products in a humid and bright place instead of somewhere dry and cold. Improper pre-roll storage may lead to the products losing their potency.

Inconsistent dosing is another common challenge companies face. They may either put too much cannabis in a pre-roll or too little. Inaccurate measurements of this kind may lead to overconsumption or weaker potency. These are two different effects that are equally damaging to the company’s image and the consumer’s health.

Source: shutterstock.com/ Photo Contributor: Creativan

Conclusion

We hope that this RocketBox 2.0 review helped you learn that the future of pre-roll production is promising. Devices with cutting-edge technology can offer great speed, unmatched precision, and versatility for businesses to satisfy their customers with the final products.